REFRACTORY BRICKS

Product Details:

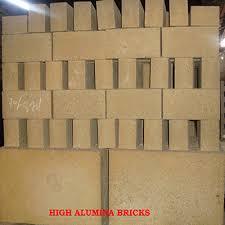

- Bricks Type High Alumina Bricks

- Material Clay

- Type Engineering Bricks

- Color Brown

- Size 9" x 4.5" x 3"

- Shape 9" x 4.5" x 3"

- Porosity Solid

- Click to View more

X

REFRACTORY BRICKS Product Specifications

- 9" x 4.5" x 3"

- Sintered

- Solid

- High Strength Fire Brick Heat-insulation Fire-retardant

- 9" x 4.5" x 3"

- Brown

- Clay

- 76.2 Millimeter (mm)

- High Alumina Bricks

- Engineering Bricks

REFRACTORY BRICKS Trade Information

- Middle East Africa Asia

- All India

Product Description

Refractory bricks, also known as fire bricks, are specialized heat-resistant bricks used in various high-temperature applications. These bricks are designed to withstand extreme temperatures, thermal shocks, and chemical corrosion. They are widely used in industries such as steel, cement, glass, ceramics, petrochemicals, and power generation to line furnaces, kilns, incinerators, boilers, and other equipment operating under harsh conditions.

FAQs:

Q: What is the purpose of refractory bricks?

A: Refractory bricks serve the purpose of providing insulation, protecting equipment from high temperatures, preventing heat loss, resisting thermal shocks, and withstanding corrosive chemical environments. They are essential for maintaining the integrity and efficiency of equipment operating at elevated temperatures.

Q: Where are refractory bricks commonly used?

A: Refractory bricks are commonly used in a wide range of industries and applications. They find extensive use in furnaces, kilns, incinerators, boilers, ladles, converters, and other high-temperature equipment. These bricks are employed in industries such as steel manufacturing, cement production, glassmaking, ceramics, petrochemical processing, and power generation.

Q: What are the main properties of refractory bricks?

A: Refractory bricks possess properties such as high-temperature resistance, thermal shock resistance, low thermal conductivity, chemical stability, abrasion resistance, and mechanical strength. These properties enable them to withstand extreme temperatures, sudden temperature changes, aggressive chemical environments, and mechanical stress.

Q: What are the different types of refractory bricks available?

A: There are several types of refractory bricks available, including fireclay bricks, high-alumina bricks, silica bricks, magnesite bricks, and chrome bricks. Each type has its own composition and properties, making it suitable for specific temperature ranges and applications. The selection of the appropriate refractory brick depends on factors such as operating temperature, chemical environment, and specific requirements of the application.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Furnace Refractory' category

We mainly deal in Chandigarh, Delhi, Haryana, Himachal Pradesh, Jammu and Kashmir, Madhya Pradesh, Uttar Pradesh, Punjab, Rajasthan, Uttarakhand etc.

Send Inquiry

Send Inquiry Send SMS

Send SMS